ABOUT US - Quality since 1959

The family-owned enterprise was founded by Kurt Allert in Leinfelden- Echterdingen in 1959, and in the following decades has established itself as a quality brand. Since 1997 we have been part of the Oetiker Group which is active throughout the world. We find that this connection works well. And connections are something we know.

Committed, highly qualified personnel, certified procedures and partnerships anchored in trust are qualities you can rely on when dealing with us. Allert stands for cross-sector flexibility, providing everything from standard products and special requirement profiles to completely new developments. Moving – holding – conveying: That's what we aspire to achieve, and our promise to our customers all over the world.

COMPETENCIES - Moving. Holding. Conveying.

Allert develops individual solutions with long service lives for connecting and conveying technology. Whether pressed parts, formed parts, conveyor belts, special chain conveyors or worm drive clamps are involved, each individual product is carefully designed, manufactured to a high quality and will perform under even the toughest production conditions.

Demanding customers in trade and industry appreciate the all-round support offered by Allert. We support you at all stages, through planning, design and implementation. What can we do for you?

DEVELOPMENT - Each production step under control

From the initial idea through to a specification with drawings – each task is different and requires sound consultation. As early as the design phase, we provide our customers with actual prototypes, and for new developments we are involved on-site right through to the start of production. Whether the requirement is simple or complex – we make it work.

Tricky requirements in the field of fastening or conveying? We love challenges. Our developers “tinker around” and create new concepts which our designers then work out in detail. Continuous improvement drives us, and numerous patents bear witness to our love of innovation. After all, tradition and obligations go hand in hand.

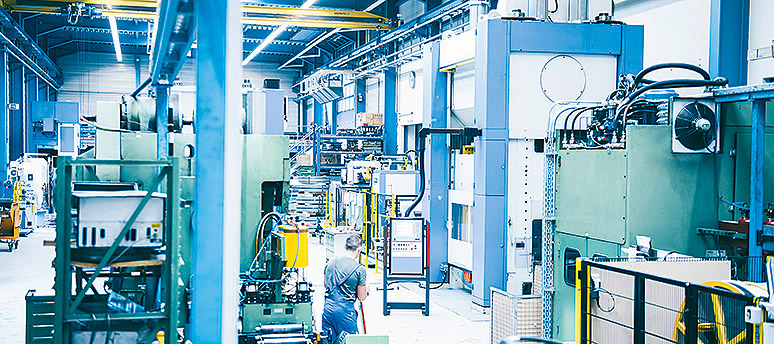

QUALITY - “Made in Germany“

When it comes to quality, we don’t compromise. We offer a comprehensive consulting service and work with you at the design phase before series productions. Allert stands for “Made in Germany” in every way. We produce in Oberndorf am Neckar, using the most modern machine tools. Allert is certified in compliance with ISO 9001and SO/TS 16949.

Come and visit us at Oberndorf a. N. and see for yourself the quality of our work. We would be equally happy to visit you directly. In a mutual discussion we can show you reliable approaches to solutions which suit your requirements.